LISTEN TO THIS ARTICLE

The Evidence of Providence -Part 2

The Engineer

By Samuel

👇 Click to translate:

How does a young man from a disadvantaged community defy a system built to limit his dreams? For me, the answer was a leap of faith, a mentor’s belief, and a relentless drive to become an engineer in a world that didn’t want me to. The next part of my story is a testament to God’s providence and the power of perseverance.

I was a qualified boilermaker with a certificate, but a conversation with my late mentor, Paul T., echoed in my mind: “You are more than a boilermaker. Study further and become an engineer.” This was a path I had to take, a journey that would test my faith, my family, and my resolve against a system determined to hold me back.

The first phase of my apprenticeship was spent learning how to interpret drawings for pressure vessels, boilers, heat exchangers, tanks, and structural steel fabrications. I learned to break down components, identify materials and shapes, and schedule my workload. In the final eighteen months, I was working as a full-fledged boilermaker. I had excelled in my training and was given the opportunity to work on my own, which helped solidify the skills Paul T. had taught me. I was a qualified boilermaker with welding tests for stainless steel and carbon steel (6G), considered the highest welding codes. I had also fallen in love with assembly work.

After my apprenticeship, I worked for several other engineering companies before returning to James Brown and Hamer. It was a couple of years after my return that Paul T. passed away. My wife and I decided it was time to honour his mentorship by furthering my studies. I had already earned my National Certificates at Levels 1, 2, and 3 (N1, N2, and N3) at LC Johnson Technical College, but to get my National Diploma in Mechanical Engineering, I needed to complete N4, N5, and N6.

By this time, I was a married man with two children. I knew that attending evening classes would take forever, but taking two years off for full-time study would be a huge financial burden on my wife, whose earning power as a non-white female in South Africa was appalling. I saw God’s hand at work in a moment of courage. I approached the college principal, Mr. Ground, and begged him to allow me to do all three courses progressively in a single calendar year—a request that had never been attempted before. He agreed on one condition: if I failed any subject, I would be immediately demoted to complete that part of the course. I accepted without hesitation.

In December 1983, I resigned from my job, turning down a training opportunity as a Project Scheduler—a position mostly reserved for white people. My focus was set on becoming an engineer. In January 1984, I began my studies. I applied myself diligently, and there was no room for failure. I successfully completed all three courses and received my diploma in 1985. I even had the distinction of winning the College Floating Trophy for Student of the Year. It was the first time anyone had ever attempted and succeeded at doing all three courses in one calendar year.

The next part of my journey was a monumental and fruitless endeavour. I was repeatedly rejected from “heavy-duty” plants in Natal (now KwaZulu-Natal). The job openings were still reserved for white people. I was deflated, but once again, God stepped in. Mr. Ground, the college principal, called me and offered me a position as a lecturer. I accepted and began teaching in mid-January 1985. I had passed subjects where there was a shortage of staff, and I had even taken it upon myself to teach my N6 Strength of Materials class when we lacked a full-time lecturer. I loved teaching and the interaction with my students.

Over the next couple of years, I passed sixteen subjects, some with distinctions, for my Technical Teachers’ Diploma. I discovered that the new principal, who took over after Mr. G retired, had been hiding a letter addressed to me, nominating me for the position of Senior Lecturer. I was angry but not hateful. It was a clear sign of the systemic prejudice that still existed. When an incident at the college led me to resign, I thought my career was over. The Chief Inspector of Education told me I would never amount to anything in the South African education system. But God had other plans.

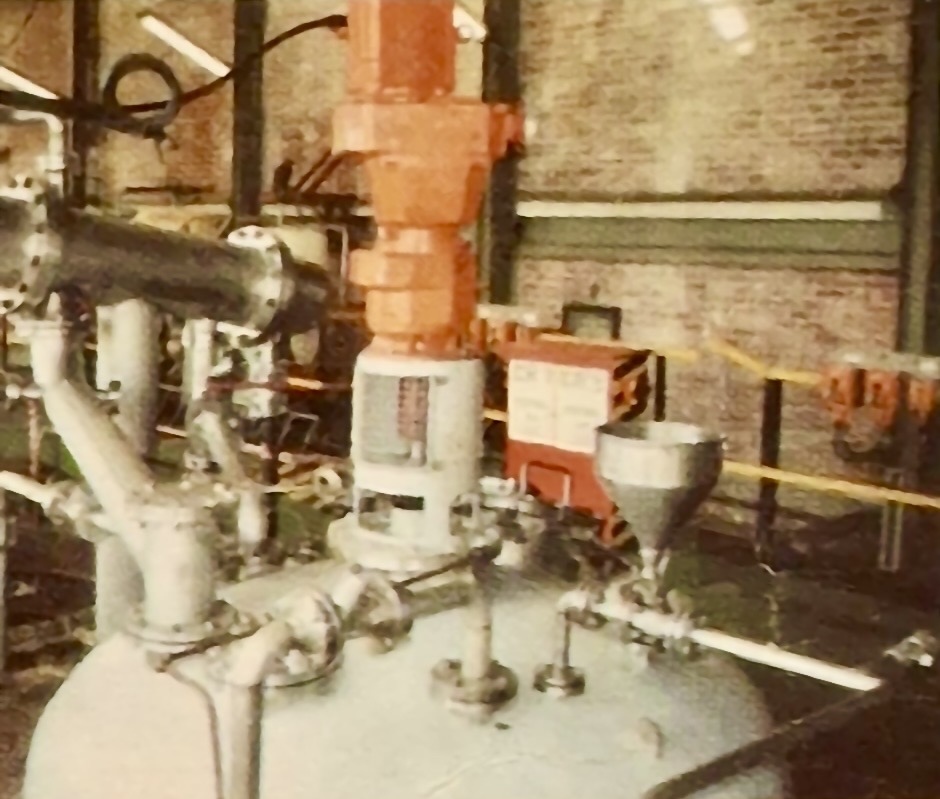

I was the Managing Director of a company called ArcForce Fabricators (Pty) Limited. We were commissioned by the AECI Group to dismantle their Tank Farm in JHB, transport the tanks and equipment to Durban and build a completely new plant using the items dismantled/salvaged. The heart of the plant, a Ten Tonne Stainless Steel Reactor, was to be designed as the original glass lined one could not be transferred without the glass lining fracturing due to transporting it overland. The glass lining was due to the highly corrosive chemicals used for producing their product. Glass-lined vessels were imported from Germany at very high cost. I did my research and assured them that we could design one for them using 904L Grade Stainless Steel. Before they placed the order for design, manufacture and installation, I was requested to see if, in my design, I could possibly have the process cycle reduced from a sixty-hour one to say thirty hours, to double their production. No Problem, I said.

I checked out the German glass-lined vessel and noticed that the exterior Hemi coil around the vessel was used to supply steam for heating to cause the production of the product, and water used for cooling for phase separation of the product. Water and steam do not mix, therefore a time frame was needed between the two activities. They were concerned as the chemicals being highly corrosive, was the reason for the glass lining. After my research, I incorporated, successfully, I might add, the following two conditions.

- I found out that the 904L Stainless Steel could withstand the chemical attacks. It was and still is a very expensive material.

- In my design I separated the steam and water processes. An external hemi coil was used for the water and an internal double coil manufactured from 904L Stainless piping for the steam. Once the design was approved, the Reactor was fabricated and installed. A day after commissioning the plant, the chief chemist came to my on-site office all excited, requesting I accompany him into the plant. There, he showed me that they had just produced their first batch with the new Reactor in just 15 hours, a quarter of the time of the original. I still look at it as one of my finest achievements.

The first ever Pressure Vessel I had designed. As the Senior Project Engineer, I had to oversee its construction plus the installation. It was a filtration type vessel to extract Toleone Oil from water.

When one door closes, another one opens. Despite possessing exceptional qualifications, I found my opportunities constrained by an oppressive system. Yet, in that challenging season, I discovered that God had a different plan for my life—one that would open doors to a career, a calling, and a purpose I could never have anticipated.

I immediately put it out to the industry that I was available for an engineering post. One of the biggest engineering companies in Durban called me in for an interview for the position of Welding Engineer. After three interviews, I was the last candidate standing. The managing director, with whom I had worked with previously, stopped the final interview and said, “I know him very well, his work ethic as well as his capabilities. Sam, this is my salary offer. I accept no arguments, and you are hired immediately.” I walked out of that office on cloud nine. It was nothing short of God showing me favour.

In my career, I’ve had many successes. I was a Quality Assurance Engineer at the Mossgas Oil Rig Main Support Frame Section. My team completed our task in eight and a half months instead of the projected twelve months. Later, on a piping project at a Durban oil refinery, our team achieved a welding failure rate of just 0.7%, a remarkable achievement. I also became a member of the South African Mechanical Engineering Institute, another God-given achievement.

In my final engineering position, I worked in the Angola Off-shore Industry for an American company as a Senior Project Engineer. Their design team had a serious problem with a new offshore installation, and for six weeks, they couldn’t find a solution. I proposed a method commonly used in pressure vessel construction: doubler plates. The head of the design department asked where I had gained that “marvellous bit of knowledge,” stating it was not found in any university or textbook they had searched. I believe it was God-given knowledge.

My journey took a difficult turn when I was eventually diagnosed with Parkinson’s disease. The headaches and vertigo I had been experiencing were early signs of this debilitating illness. I had not been sidelined from my comfortable career, but I now feel comfortable as a blogger. One of my closest friends recently told me, “Brother, you were born for a time like this.” His words were profound and reassuring.

There is an African proverb: “If you want to go fast, go alone. If you want to go far, go together.” I want to go far, so I invite you to travel with me on this journey. To God be all the glory for his providence.

At Samuelshares.com you’ll never be blogged down but always uplifted!

Liked what you read? click below & Share!

In reading this blog now, I can make this statement, thus is not a unique one but is duplicated in the lives of many people all over the world and not only in engineering but in all job descriptions across the working environment. We all have a story to tell.

That is such a profound and absolutely true observation. Thank you for sharing it.

You hit the nail on the head—while my story is personal, the underlying struggles, triumphs, and lessons aren’t unique at all. It’s truly a universal experience that plays out across all job descriptions and all industries, not just engineering.

I completely agree: We all have a story to tell. And often, reading someone else’s story is what helps us recognize the similar chapters in our own lives.

I appreciate you taking the time to read and reflect on that bigger picture! 😊

Thank you so much for your kind and thoughtful comment.

Sharing my personal experience with Parkinson’s disease was a decision I made in the hope that it might offer some clarity, comfort, or encouragement to others facing similar challenges. I truly trust, as you do, that it will be helpful to those who read it.

Your well wishes are deeply appreciated. I hope to continue sharing and being an encouragement to others during this season. Thank you again for reading! 😊